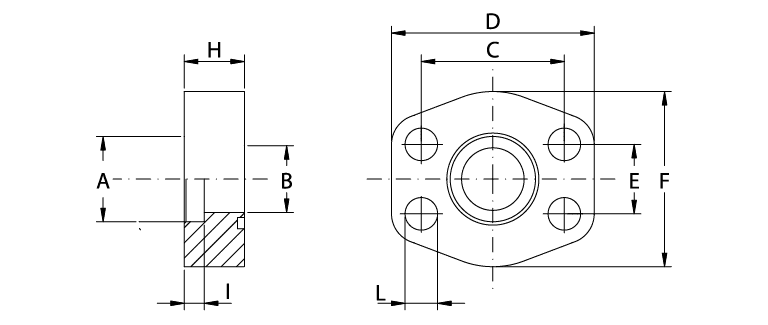

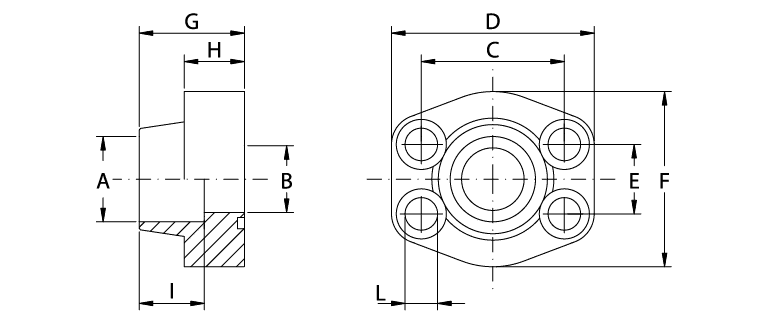

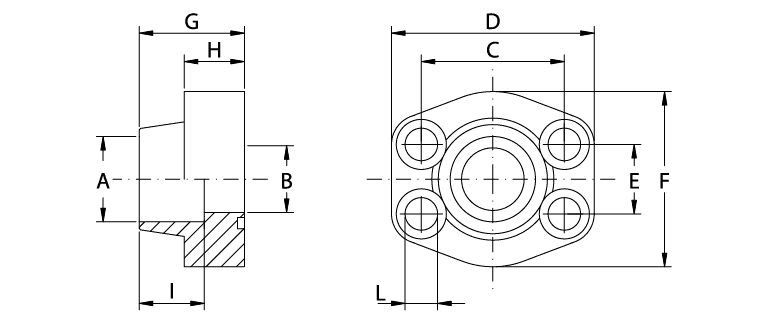

Weld in Flanges

The main feature of weld in flanges is the presence of a pocket or cavity inside the flange, where the pipe is inserted before welding. This design facilitates the correct alignment of the pipe during the welding process.

Technical features

Weld in flanges are generally made in carbon steel or stainless steel, to withstand the environmental conditions typical of oil-hydraulic systems.

The internal socket ensures that the pipe is positioned correctly during welding, reducing the risk of misalignment and improving the integrity of the connection.

Compliance with SAE standard ensures that flanges are designed to withstand the high pressures and operating conditions in oil-hydraulic systems.

Applications

Weld in flanges are generally made in carbon steel or stainless steel, to withstand the environmental conditions typical of oil-hydraulic systems. The internal socket ensures that the pipe is positioned correctly during welding, reducing the risk of misalignment and improving the integrity of the connection. Compliance with SAE standard ensures that flanges are designed to withstand the high pressures and operating conditions in oil-hydraulic systems.

Get in touch with us

Do you need information about SAE weld in flanges? Contact us, our technical office is always available to provide analysis, advices and a free quote.